287.34(M1)

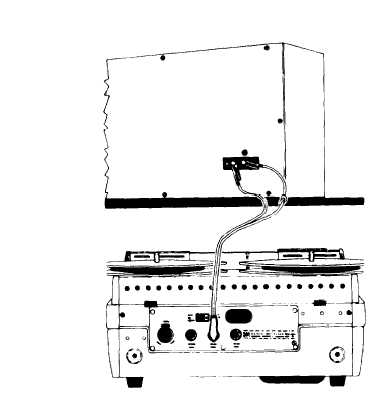

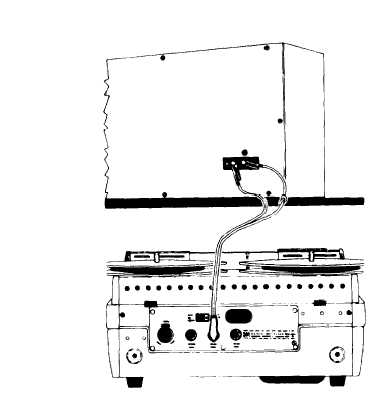

Figure 7-22.—Playback through extension speaker.

Minor Maintenance

You can expect to do very little maintenance

on tape recorders. Occasional] y, you may have

to clean surfaces or change pressure pads but, as

a rule, if more complicated maintenance is

required, you should return the recorder to your

maintenance department.

PRESSURE PADS.—If the pressure pads

do not hold the tape firmly against the heads,

poor sound will result. With the machine on and

in the PLAY position, check to see if the two felt

pads are worn or are not pressing the tape

squarely against the head pole faces. When

necessary, the felt pressure pads furnished for

replacement may be cemented in place with

household cement. The pads should cover the

shiny pole faces of the heads, and the side of

each pad touching the head must be free of

cement.

LUBRICATION.—Generally, all moving

parts of a tape recorder are permanently

lubricated, and with normal use no further

lubrication should be necessary.

Cleaning

The majority of defects, other than wear or

breakage, can be traced to dirty surfaces. The

play-record and erase heads, capstan, and

pressure roller are subject to an accumulation of

tape coating residue, which is rubbed off the

tape as it passes these parts. This accumulation

will cause faint recording and poor playback and

will impair the ability to erase. Therefore, the

accumulation must be removed periodically.

Remove the accumulation by wiping off the

record and erase heads, capstan, and pressure

roller with a clean cloth. If dirt is caked or hard

and will not come off with a dry cloth, dampen

the cloth slightly with alcohol.

7-43